Performance Materials to Precision Products in Processing of Manufacture for Semiconductor

SHANGHAI TECHINITAL MATERIALS CO.,LTD

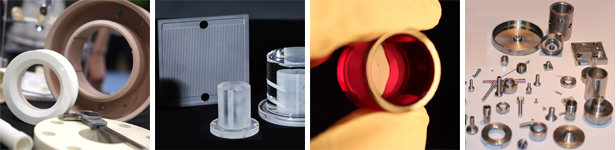

High-Precision Machining of Hard Materials

Techinital specializes in high-precision machining of hard materials such as technical ceramics, ruby, industrial sapphire and tungsten carbide.

Thanks to our long experience in the machining of hard materials, we have become a leader in this specialized field.

The company can make high-tech parts to customer specifications in the hardest materials and thereby supply high-quality mounted assembies resolving all problems of wear, electrical insulation, corrosion resistance or high temperatures.

Ruby and Sapphire

We are specialized in precision drilling,grinding,polishing and machining with diamond bits of all technical parts made of synthetic sapphire,one of the hardest materials in the world after diamonds. (average hardness of about 1900 vickers,9 on the Mohs scale).

Industrial Sapphire components used in a range of semiconductor equipment applications:

sapphire tubes,

plasma injector nozzles,

sapphire chamber windows and viewports,

Sapphire lift pins,

Optical light guides and sensor probes,

Thermocouple protection sheaths,

Gas delivery and shower head components.

Sapphire and Ruby are actually the same material with small amounts of chromium (typically ≤ 0.05% by weight) added which affects color and optical properties, while not affecting mechanical, thermal and electrical properties significantly.

Advance Ceramics

Advance ceramic is also referred to as technical ceramic,engineering ceramic or industrial ceramic.These materials cover many different and in part highly-specialized ceramic materials with unique mechanical,electrical,thermal and biochemical properties and property combinations.

Techinital provides finished parts to tight tolerance from most advanced ceramics including alumina,zirconia,quartz,silicon carbide(sintered or CVD),silicon nitride,and especially high grades of sapphire.

From raw material design and production to finished and assembled components,our vertically integrated manufacturing ensures quality for every step of the process.

Ceramic machining and grinding services from prototype to mass production

Techinital offers custom precision ceramic machining and grinding services of tight tollerance components to a broad range of industries.We employ a wide range of ceramic machining and grinding methods.We specialize in working with clients to arrive at solution options that offer the best value for their particular application.

Ceramic injection molding

Ceramic injection molding is ideal for high volume production of complex,tight tolerance components,ceramic injection molding offers significant advantages over conventional forming methods:

- Cost-effective for complex designs

- Ability to achieve net or near-net shape parts.

- Very tight tolerance control

- Low-cost,high-volume manufacturing runs

Tungsten Carbide

Our company with years of experience manufacturing quality precision fabricated parts made out of tungsten carbide (cobalt or cobalt and nickel),tungsten heavy metal alloys,pure molybdenum,pure tantalum and pure tungsten.

The main advantage for our clients is our ability to understand and resolve problems at all stages of the project, from prototype engineering to the mass production of high-precision tungsten carbide parts.

DSC TGA SDTA Industrial Sapphire Crucible and Cover for Thermal Analysis

Our synthetic sapphire or ruby crucibles for thermal analysis are made of raw material alumina with purity >99.9%. The extreme high purity and 100% density allow the crucibles to perform excellent chemical inertness, wear resistance, high thermal shock resistance and high temperature resistance. It is translucent and offers optical transparency.

Sapphire is a very pure form of monocrystalline aluminum oxide.This is the reason why a sapphire crucible is chemically more resistant than a polycrystalline alumina (aluminum oxide) crucible. The crucible is also recommended for melting metals such as Fe and Ni.

We specialize in the most frequently used DSC sample pans and custom design by customer.

Hard Materials Machining

Email: 13917175219@139.com

Performance Materials to Precision Products

in processing equipment of Manufacture for

Semiconductor

About Techinital

We are committed to the optimization of the machining process, the selection of the most appropriate machining equipment,

to ensure products accuracy at the same time, to provide best cost solution to the user.

We are committed to selecting the raw material with stable quality from our long term cooperated raw material mill,

as we know high proformance products depand high quality raw materials in the applications of refractory metal.

©2017 Techintial Materials

Contact Techinital

Factory: No.04-06, Building 3, XM Industrial Zone, Economy&Technology Development District, Guiyang City, Guizhou China

Office: Room 2030A-B, No.212, Road Jiangning, Shanghai China

Email: 13917175219@139.com

HP: +86 13917175219